Hello friends! This is a warm-up article for analog and digital signals in industrial systems. Sounds similar to how machines in factories communicate with one another, right? Except they communicate via signals. Go down the rabbit hole of analog signals and digital signals with me.

Analog vs Digital Signals

Analog signals which are essentially the waves that come in varying amplitudes and frequencies. They are continuous, which can even take a value within an interval. In stark contrast, digital signal are very much like codes that make use of only two values, which are 0 and 1.

Benefits of Using Digital Signals in Industrial Systems

There are many benefits associated with digital signalling in industrial environments. One of these main advantages is their relative immunity to noise and interference. That hybrid inverter implies more precise and dependable information are transmitted as well.

Examples of Analog Signals in Industrial Applications

Analog signals are also commonly used in industrial processes. Analog signals in temperature sensors, for instance, measure and transfer the necessary data to check the temperature of machines or equipment. Analog signals are too used in pressure sensors to measure the pressure inside pipes and tanks.

Integrating Analog and Digital Signals

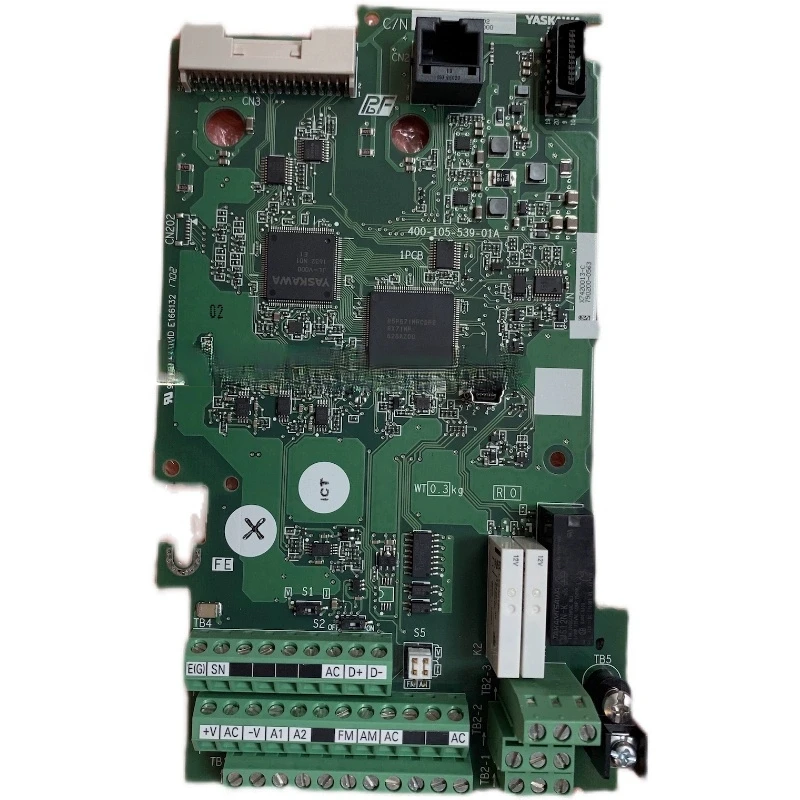

Industrial systems need to mix analog and digital signals in some instances. It is because of some sensors produce an analog output and the control systems take digital input. Hybrid solar inverterConverters are used to handle these situations which convert analog signals into digital information that can be digitized by the machine. By integrating, coordination is ensured all across the industrial system.

The Future Of Analog And Digital Integration For Industrial System Design

This because as technology advances, the fusing of analog and digital signals in industrial systems will continue to be significant. This inverter combination will also make it easier for one machine to talk to another and ultimately improve your effectiveness saving you money in the long run. These sensors and converters are only going to get better, becoming more advanced in helping you further integrate these devices into the enterprise of tomorrow.

Conclusion

Although analog signals are problematic why to digital is almost always more beneficial, I still believe in building it and how you can wire this thing. Combining these two types of signals enables industrial processes to function with far greater efficiency and reliability. With our focus on the horizon, it is clear that analog and digital signal integration remains a key driver of more innovation and improvement within industrial environments.