In the landscape of industrial automation, the precise control and efficient operation of small - scale equipment are crucial for enterprises to achieve production optimization. As a leading brand in the industrial field, the PLC modules of Siemens' S7 - 200 SMART series are emerging as an ideal choice for small - scale automation scenarios, especially shining in industries such as food processing.

High Cost - Effectiveness and Flexible Expansion to Adapt to Diverse Needs

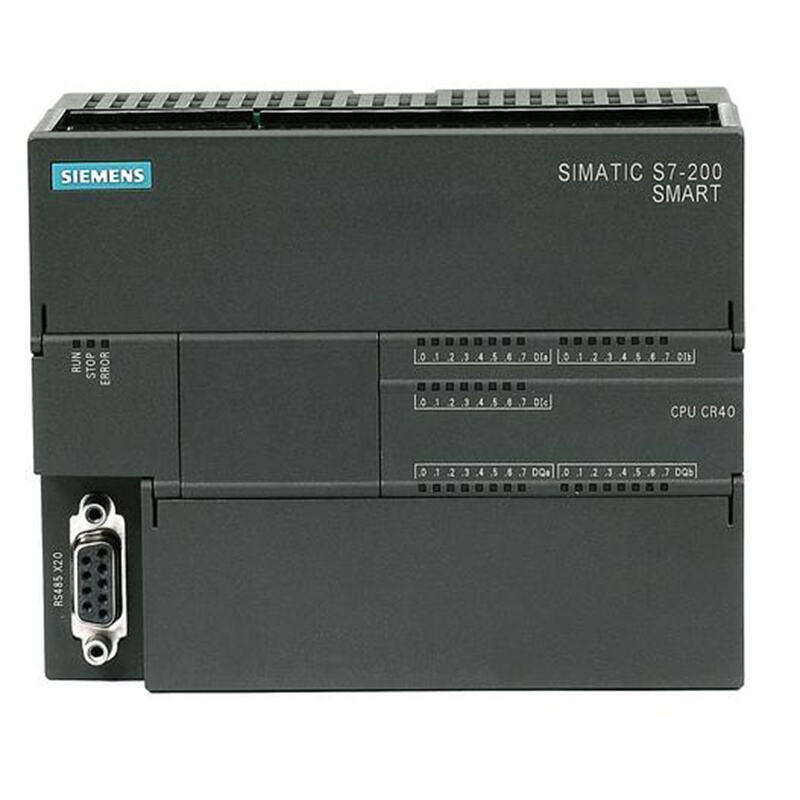

The Siemens S7 - 200 SMART series, such as models like CPU ST20 and CPU ST30, is tailor - made for small - scale automation equipment and has the advantage of high cost - effectiveness. While controlling costs, it builds a stable and reliable automation system. Take the CPU ST20 as an example; it has an I/O configuration of 12 inputs/8 outputs, which can meet the control requirements of basic small - scale equipment. The CPU ST30, on the other hand, expands to 18 inputs/12 outputs, capable of handling slightly more complex control scenarios with ease.

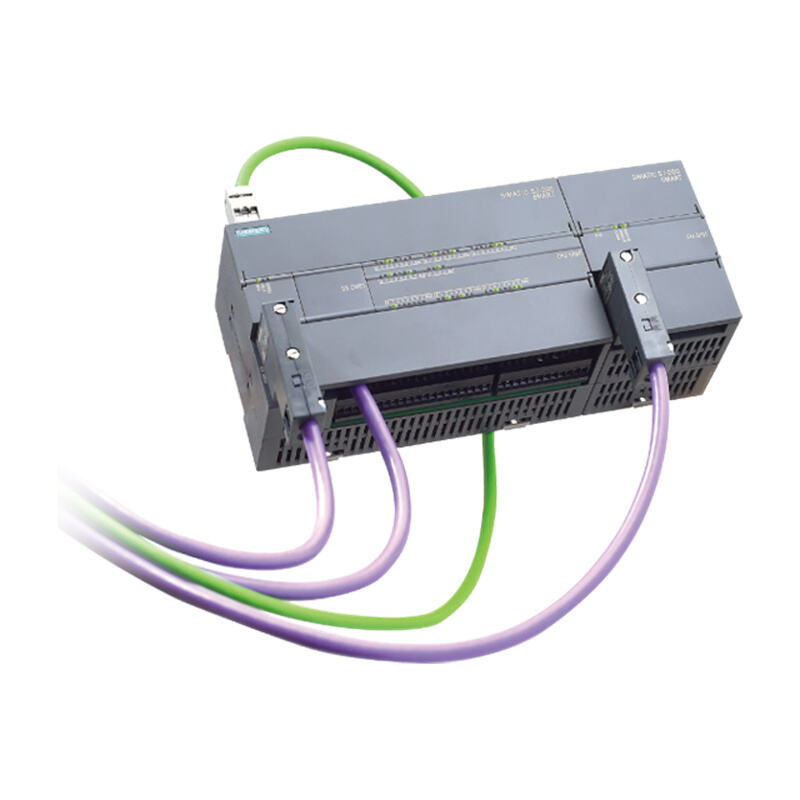

This series features excellent flexible expansion capabilities and supports connecting various expansion modules such as the EM DI08 digital input module and the EM AQ02 analog output module. Enterprises can freely add input - output points and expand communication functions according to production needs, allowing the system to flexibly upgrade with business development and easily adapt to the automation requirements of different links in food processing, from raw material handling to finished product packaging.

Empowered by Communication Modules for Real - Time Data Interaction

When paired with the CM 01 communication module, the S7 - 200 SMART series can build an efficient data channel to achieve **real - time collection and transmission of production data**. In the food processing scenario, taking a baking production line as an example, from the flow data of flour transportation, parameters such as oven temperature and baking duration, to the quantity statistics of finished product packaging, the equipment operation information can be accurately synchronized to the management system. Relying on this real - time data, enterprise managers can timely adjust production strategies, optimize process flows, and ensure the **efficient and orderly** progress of production, avoiding efficiency losses and mistakes caused by information lag.

Deeply Engaged in Small - Scale Industrial Scenarios such as Food Processing

The food processing industry has specific requirements for control precision and production continuity, and the control logic is relatively simple. The S7 - 200 SMART series, with its easy - to - use programming environment and stable control performance, becomes a capable assistant in this field. In the automated production lines of small - scale food processing plants, whether it is the forming, baking, and packaging links in biscuit production or the liquid level control and filling speed adjustment of beverage filling equipment, models like the CPU SR40, with its configuration of 24 inputs/16 outputs and the ability to handle complex logic, can be accurately adapted. It helps enterprises improve the level of production automation, reduce mistakes caused by manual intervention, and ensure stable product quality.

With Dual Guarantees of Quality and Service

As a classic PLC series, the S7 - 200 SMART inherits the brand's rigorous craftsmanship and reliable quality. From hardware design to software adaptation, it has undergone strict industrial environment testing and can cope with challenges such as humidity and dust in food processing workshops. At the same time, Our complete after - sales service network and technical support enable enterprises to obtain professional assistance throughout the entire process of equipment selection (such as matching models like CPU ST20/ST30/SR40 according to production scale), commissioning, and operation and maintenance, without any worries. Under the wave of Industry 4. 0, the upgrade of small - scale industrial automation is imperative. The Siemens S7 - 200 SMART series, with its high cost - effectiveness, flexible expansion, and data interaction capabilities, provides an efficient automation solution for small - scale industrial scenarios such as food processing. It covers a rich range of models including CPU ST20, ST30, and SR40, helping enterprises to steadily move forward on the path of cost reduction, efficiency improvement, and intelligent transformation, and becoming the preferred brand series for the control of small - scale automation equipment. Core engines to capture relevant keywords and improve content exposure.

Hot News

Hot News2025-07-14

2025-07-12

2025-07-02